Needles DBX1 SERV 7, 16X231 SERV 7, 287 WH SERV 7, 1738 SERV 7 (10 pcs)

1.80€

Increased needle stability and reliable seams.

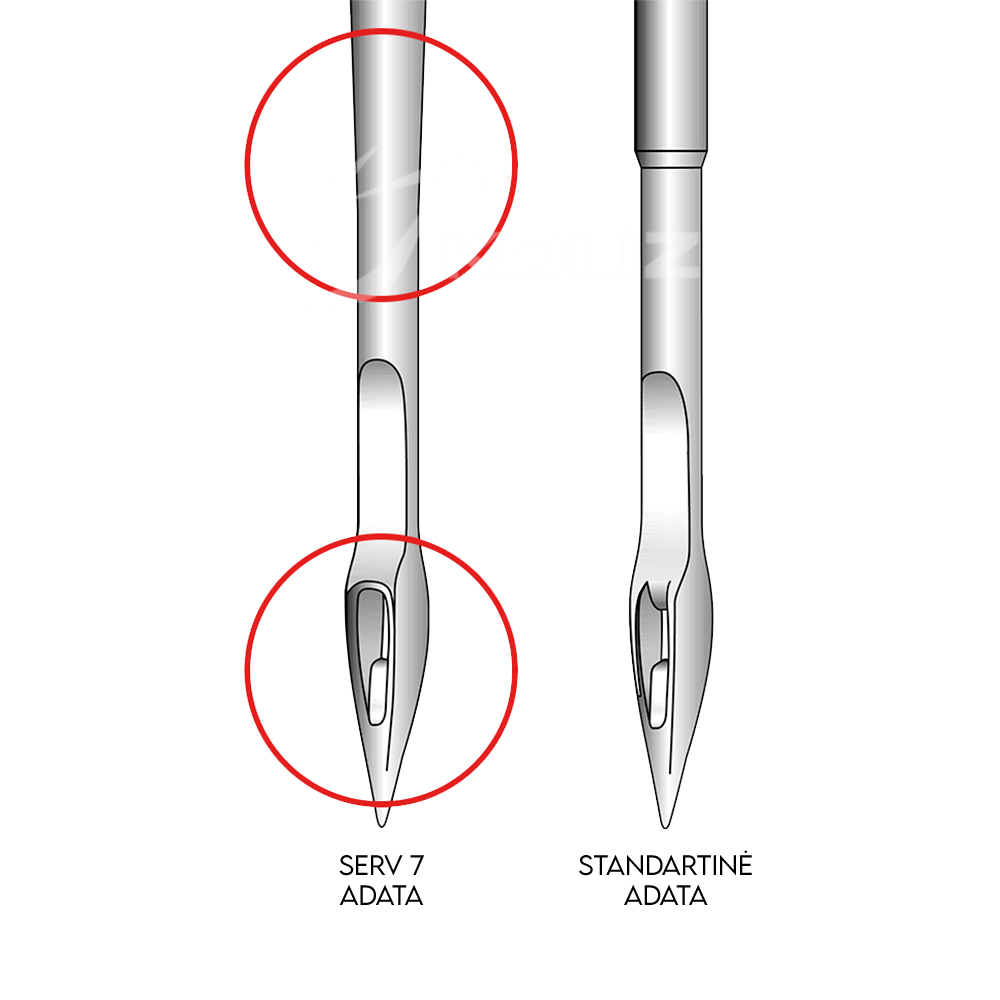

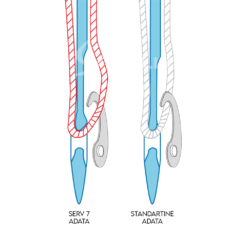

The main distinguishing features of the SERV 7 design are the hump scarf that makes a particularly large loop of thread which can be more easily caught by the point of the hook and the blade reinforcement, that ensures the extraordinarily high stability of the needle.

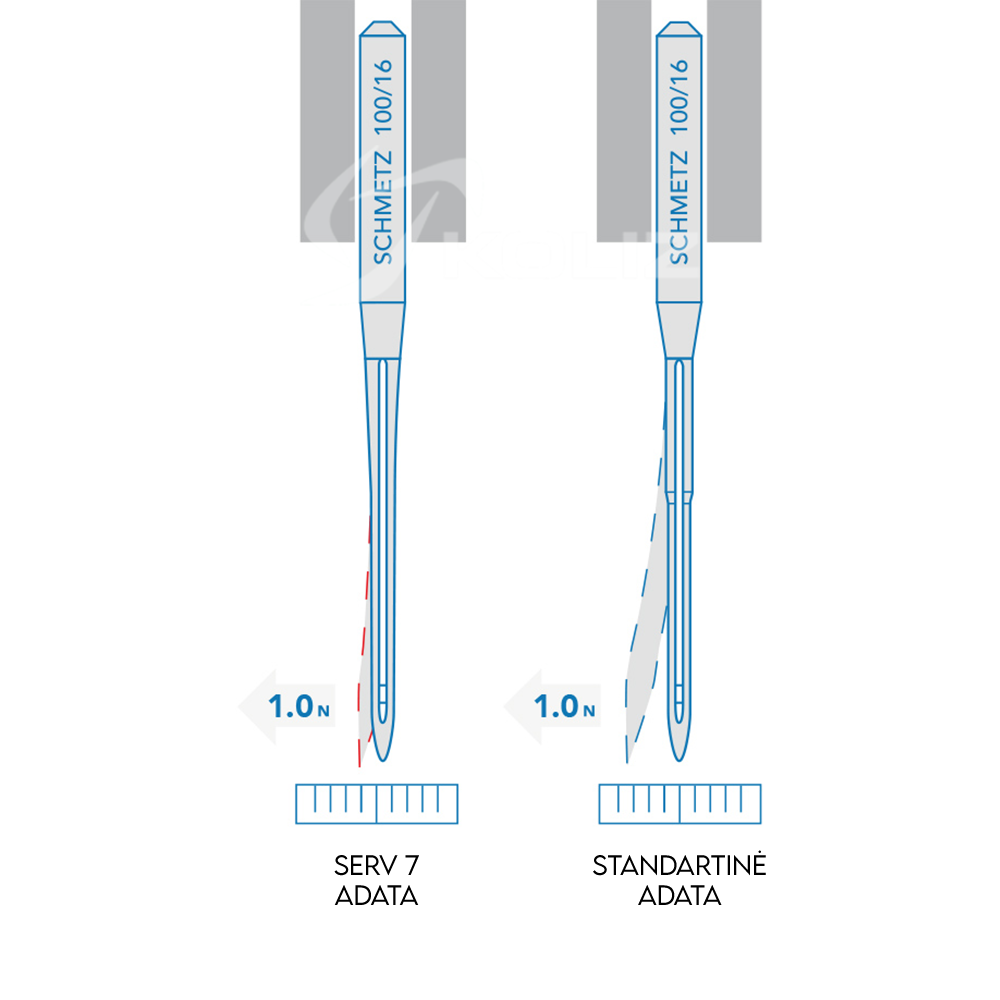

To produce the smallest possible stitch holes and optimise fabric displacement, the SERV 7 design thus often allows the use of a needle one size smaller without any reduction in the stability of the needle.

SERV 7 needles have a 15% reinforcement, and as much as 20% in some needle sizes. Therefore, the needle is especially stable and far less likely to “bend”.

The special stability of the SERV 7 needle is particularly valuable for use with thick materials and multiple layers of fabric, such as in sewing cross seams in jeans manufacture. Other classic instances of deployment of SERV 7 needles are in production of interior upholstery for the car industry, but also for the processing of particularly fine materials.

Point shapes:

Normal round point “R”

The normal round point is the standard point form and has a slim, conical shape. No point supplement “R” is mentioned in the system code.

Applications:

- Light woven fabrics.

- Coated materials, heavy woven materials, e.g. tent awnings.

- Laminated materials with soft plastic or thin cardboard.

- Films.

- Leather/textile combinations.

Light ball point “SES”

The light ball point displaces woven and knitted threads, directly piercing the spaces, and avoiding damage to the material.

Applications:

- Fine to medium knitwear.

- Light denim materials.

- Light, densely woven materials.

- Medium to heavy woven fabrics.

- Laminated materials (textile/textile).

Medium ball point “SUK”

Needles with a medium ball point are rounder than the “SES” light ball point.

Applications:

- Medium to coarse denim materials.

- Coarse knitwear.

- Manufacture of corsetry.

Acute round point “SPI”

Needles with an acute round point “SPI” that is very slim, allow accurate piercing of densely woven and coated materials. Additionally, this point shape enables you to get exact seam appearance while avoiding seam puckering.

Applications:

- Very densely woven materials, e.g. microfabrics, silk.

- Thin, coated materials.

- Thin, smooth materials, e.g. taffeta.

- Normal seams in shirt stitching (shirt collars, cuffs).

- Non-covered elastomeric threads.

- Manufacture of fur garments and skins.

| Size | 100, 60, 65, 70, 75, 80, 90 |

|---|---|

| Tip type | R, SES, SPI, SUK |